FOOD PROCESSING & AUTOMATION

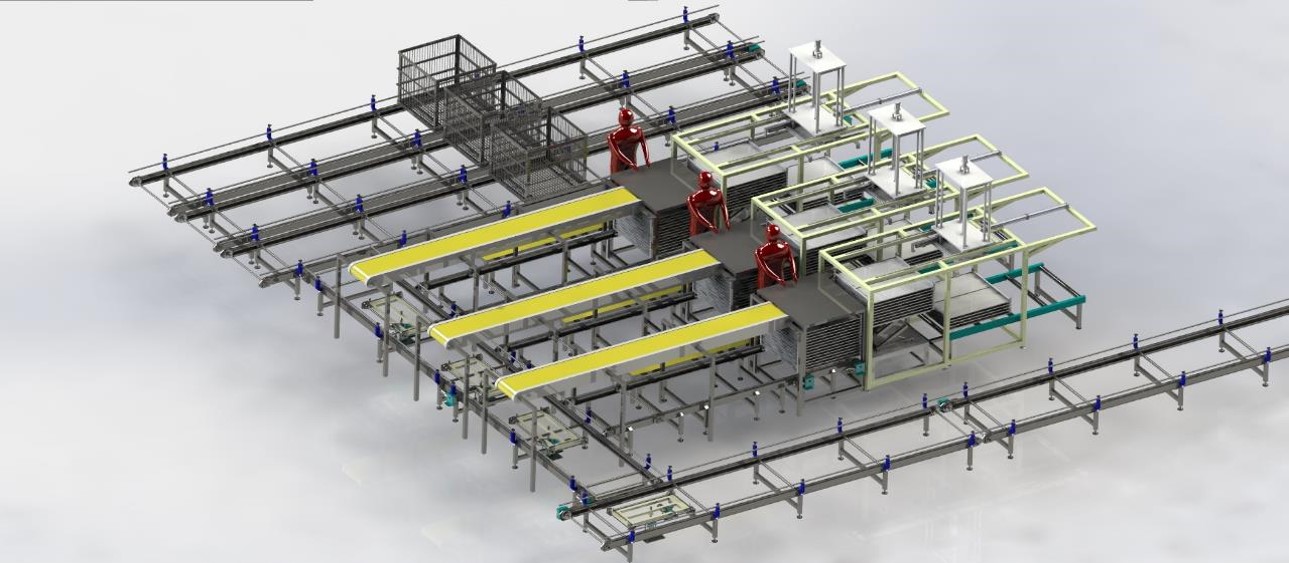

Can-Cup & Pouch Food Processing Machinary Line

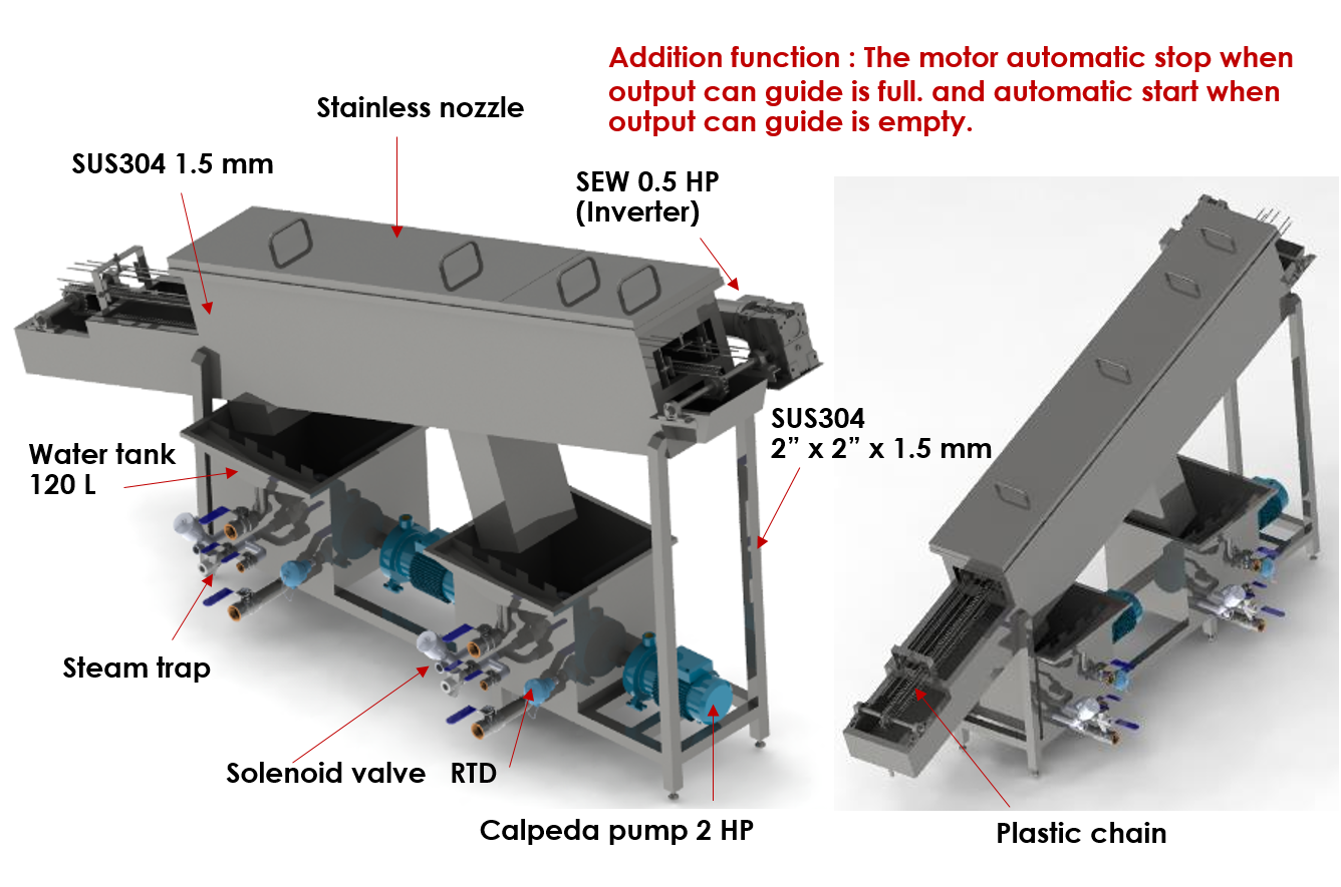

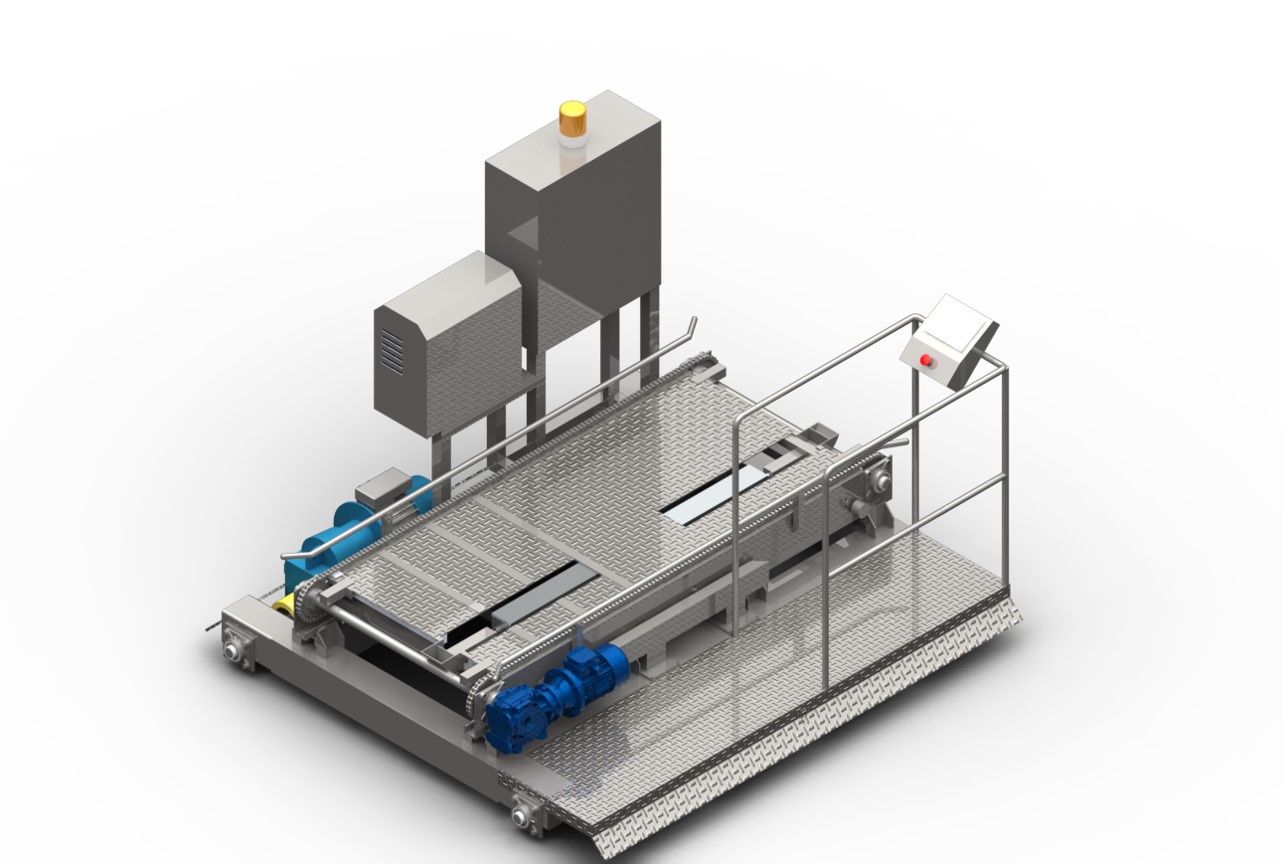

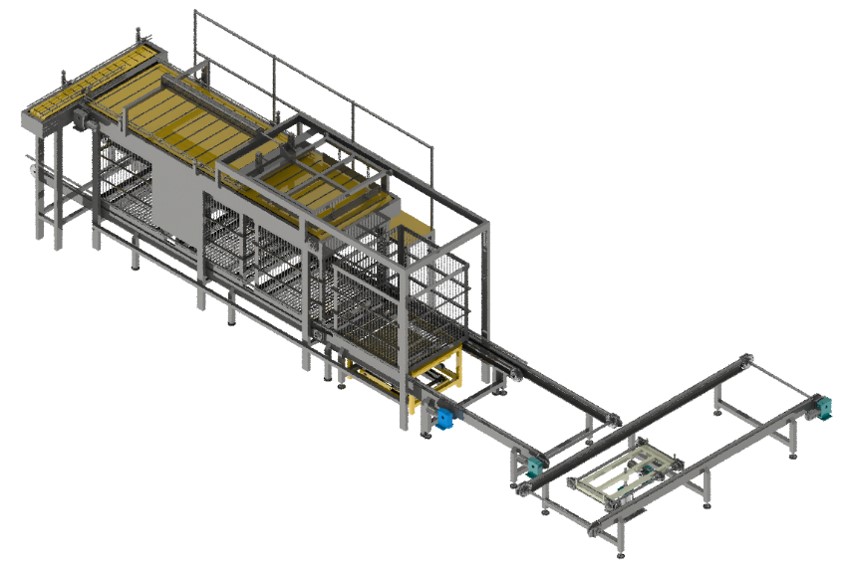

Can Washer

Dual zone can washer

•Size : 500 x 3,400 x 1725 mm

•Frame : Square pipe 2”x2”,t 1.5 mm

•Body : SUS304, t1.5 mm

•Capability : 180 – 200 cpm

•Inlet : 600 mm Outlet : 1700 mm

•Triple spray zone : Detergent

+ hot water (Circulation)

: Hot water (Circulation)

: Cold water

•Circulate pump : Calpada 2 HP

•Motor Gear : Sew 0.5 HP

•Inverter : Hitachi

•Temperature control : Omron

•PLC : Allen Bradley

•Control panel : SUS304

•Steam valve : Solenoid valve

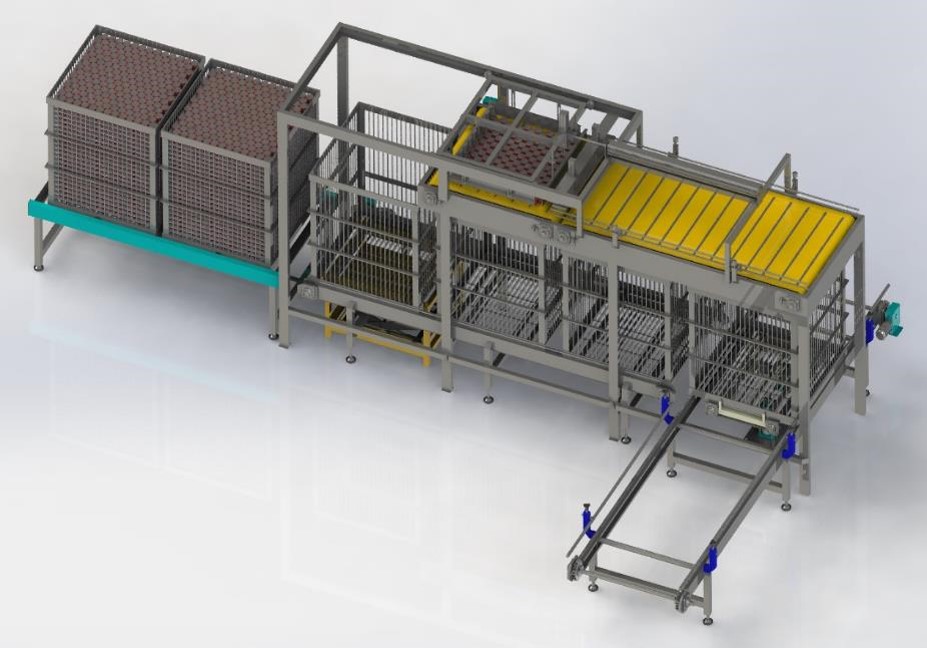

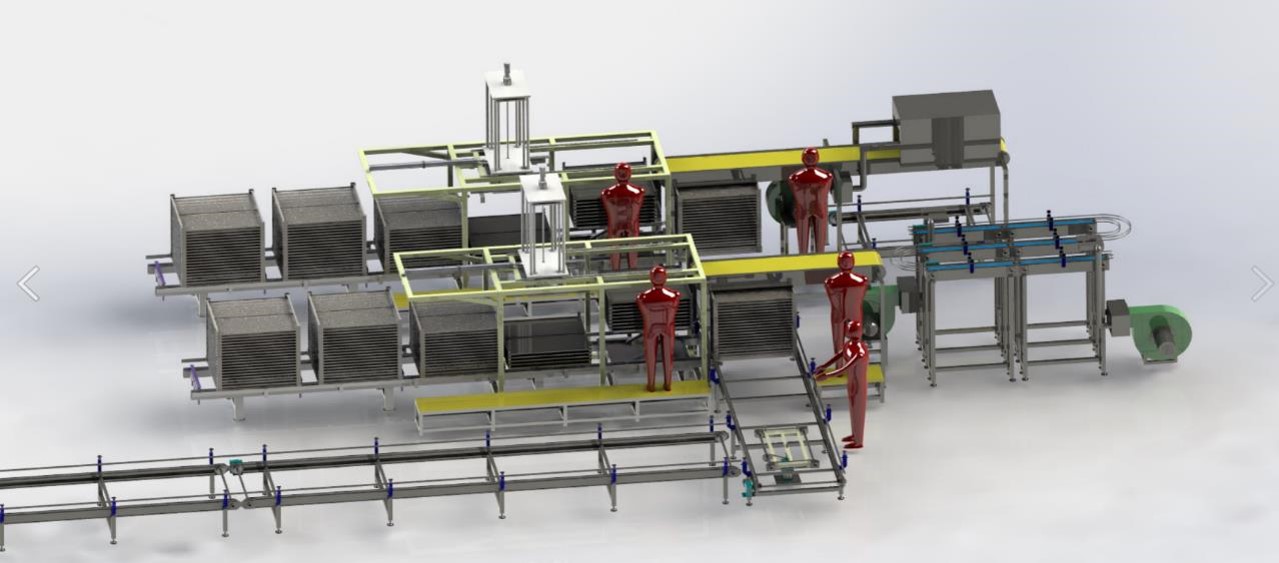

Semi Automatic basket Loader

Semi-Auto Basket loader

•Size : 1,000 x 4,600 x 1,650 mm

•Frame : Pipe 3”x 1 1/2”,t 3 mm

•Body : SUS304, C Frame t 3 mm

•Platform : SUS304, w=500 mm, 2 sides

•Motor Gear : Sew 1 HP, 30 rpm

•Capability : 180 – 200 cpm

•Conveyor : Modular belt

•Pneumatic cylinder : SMC

•X lift: Hot Dip Galvanized Steel

•Hydraulic : SUS tank 40 l., motor 2 HP

•Inverter : Hitachi

•Sensor : Photo, Reed, Limit switch

•PLC : Allen Bradley

•Control panel : SUS304

•Mode: Semi automatic / Manual

Semi Automatic Cup & Pouch Loader

Semi-Auto Cup & Pouch loader

•Size : 1,000 x 4,600 x 1,650 mm

•Frame : Pipe 3”x 1 1/2”,t 3 mm

•Body : SUS304, C Frame t 3 mm

•Platform : SUS304, w=500 mm, 2 sides

•Motor Gear : Sew 1 HP, 30 rpm

•Capability : 180 – 200 cpm

•Conveyor : Modular belt

•Pneumatic cylinder : SMC

•X lift: Hot Dip Galvanized Steel

•Hydraulic : SUS tank 40 l., motor 2 HP

•Inverter : Hitachi

•Sensor : Photo, Reed, Limit switch

•PLC : Allen Bradley

•Control panel : SUS304

•Mode: Semi automatic / Manual

Semi Automatic Loader Tray Stacker

Semi-Automatic Loader tray stacker

Specification

•Main Frame : SUS.304 Square pipe 2″ x 2″ x 1.5 mm

•Support Frame : SUS.304 Square pipe 1 1/2″ x 1 1/2″ x 1.5 mm

•Buffer table : SUS304 sheet, size 1000 x 1000 x 1.5 mm

•X- Lift : Mild steel with hot dip galvanized with Hydraulic power unit set

•PLC : Allen bradley completed with weintek touchscreen 7“

•Servo motor : Mitsubishi for vertical movement

•Inverter : Hitachi

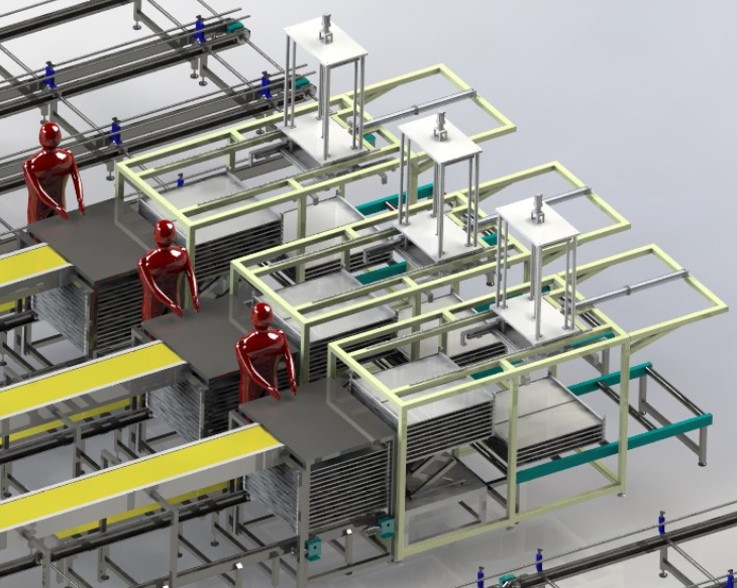

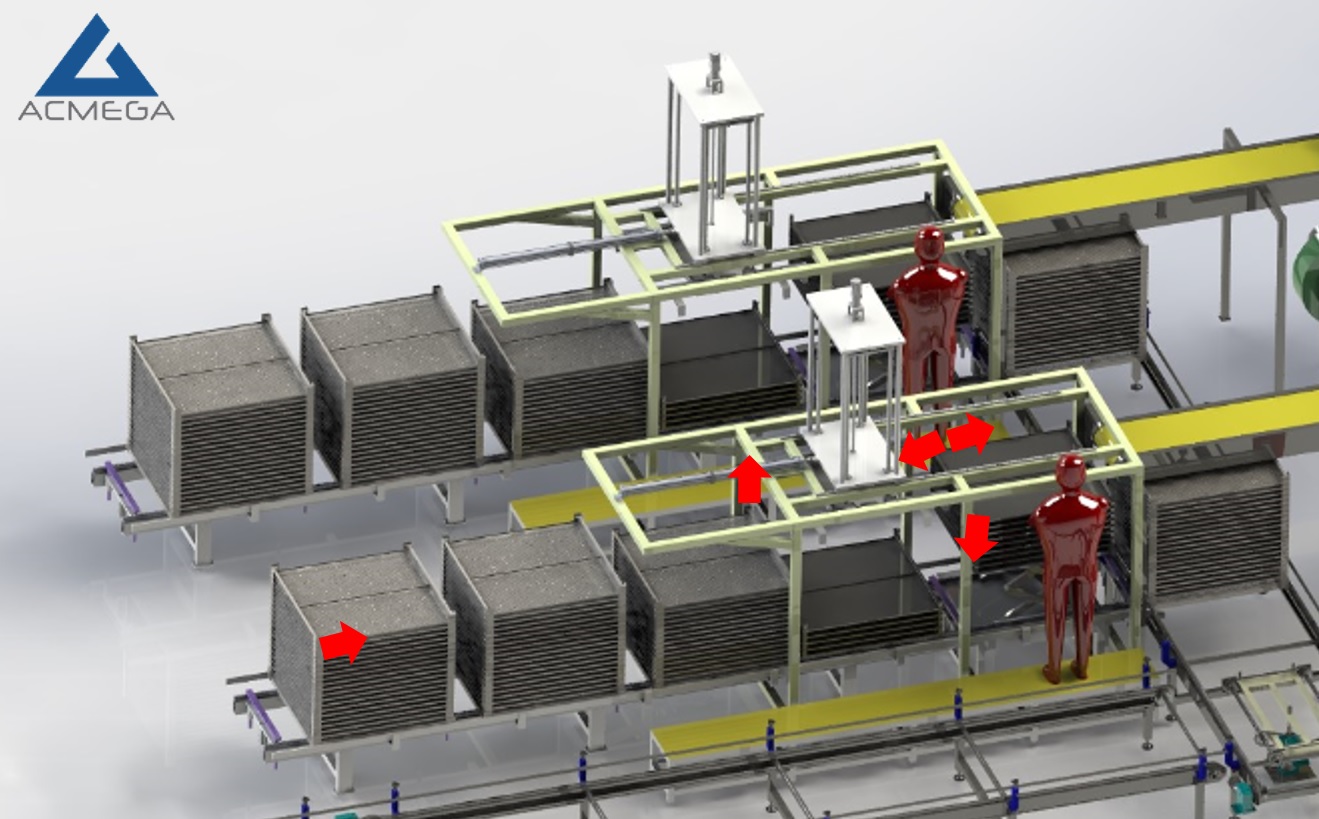

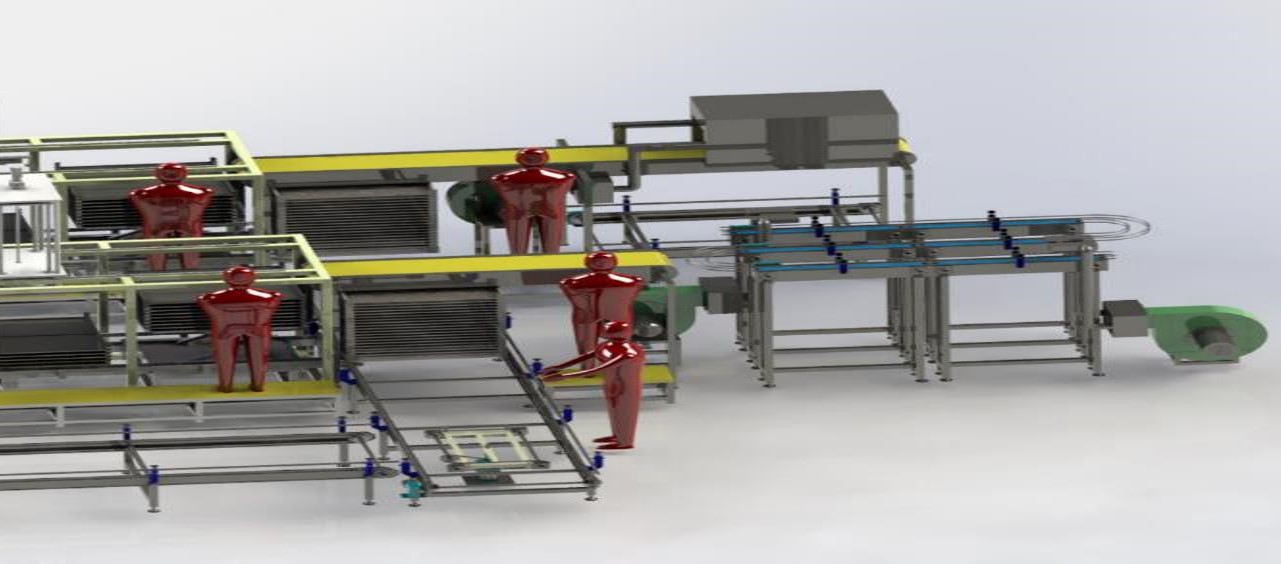

SemInfeed Automatic Guided Vehicle (AGV) / Shutter

Infeed 2 baskets shuttles with rail system

•Size : 1,500 x 2,000 x 550 mm•Frame : SUS304, C shape, t = 3 mm

•Wheel : Stainless 4” and 2”•Platform : SUS304, w=500 mm, 1 side

•Basket guide : Pipe ¾”•Motor Gear : Sew 1 HP for extender motor (fix speed)

2 HP for feeding motor(fix speed)

2 HP for driving motor (fix speed)

•Chain : Stainless chain #60

•PLC : Allen Bradley

•Control panel :SUS304•Option : Pneumatic pusher

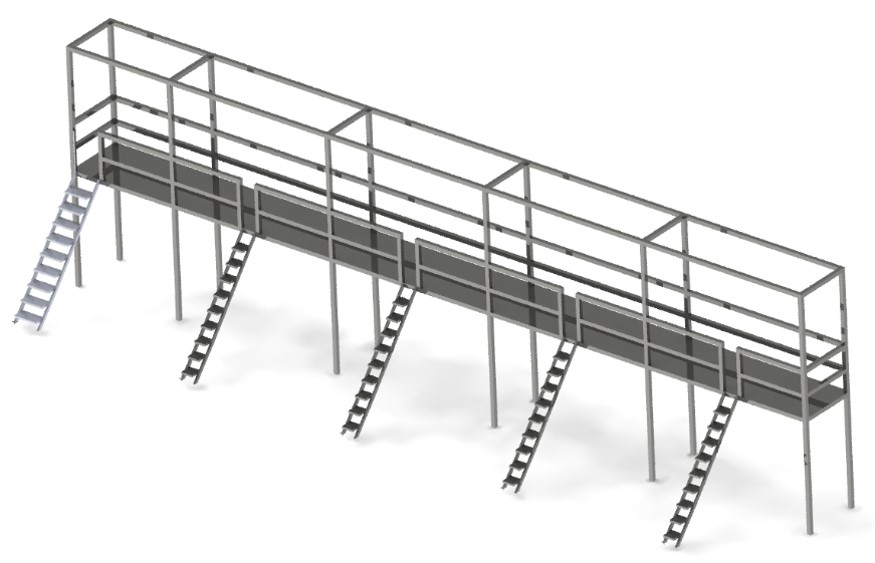

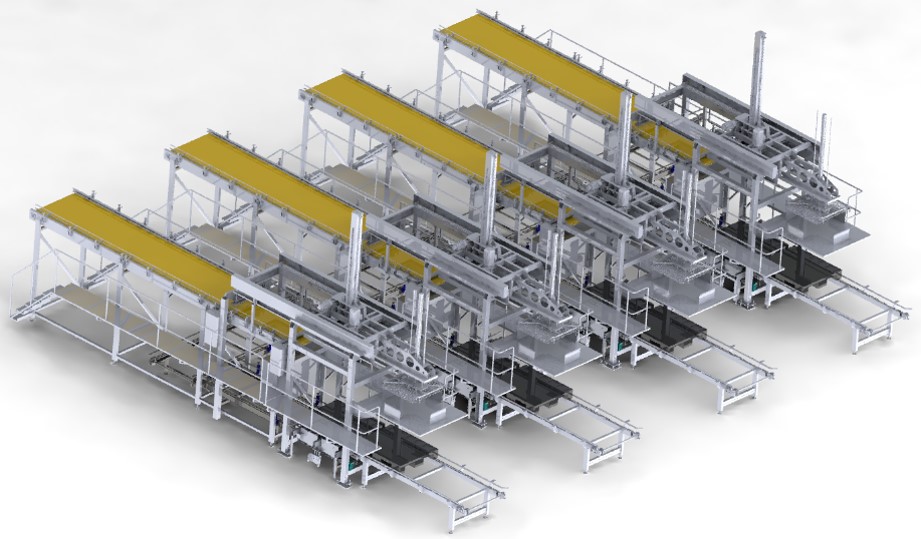

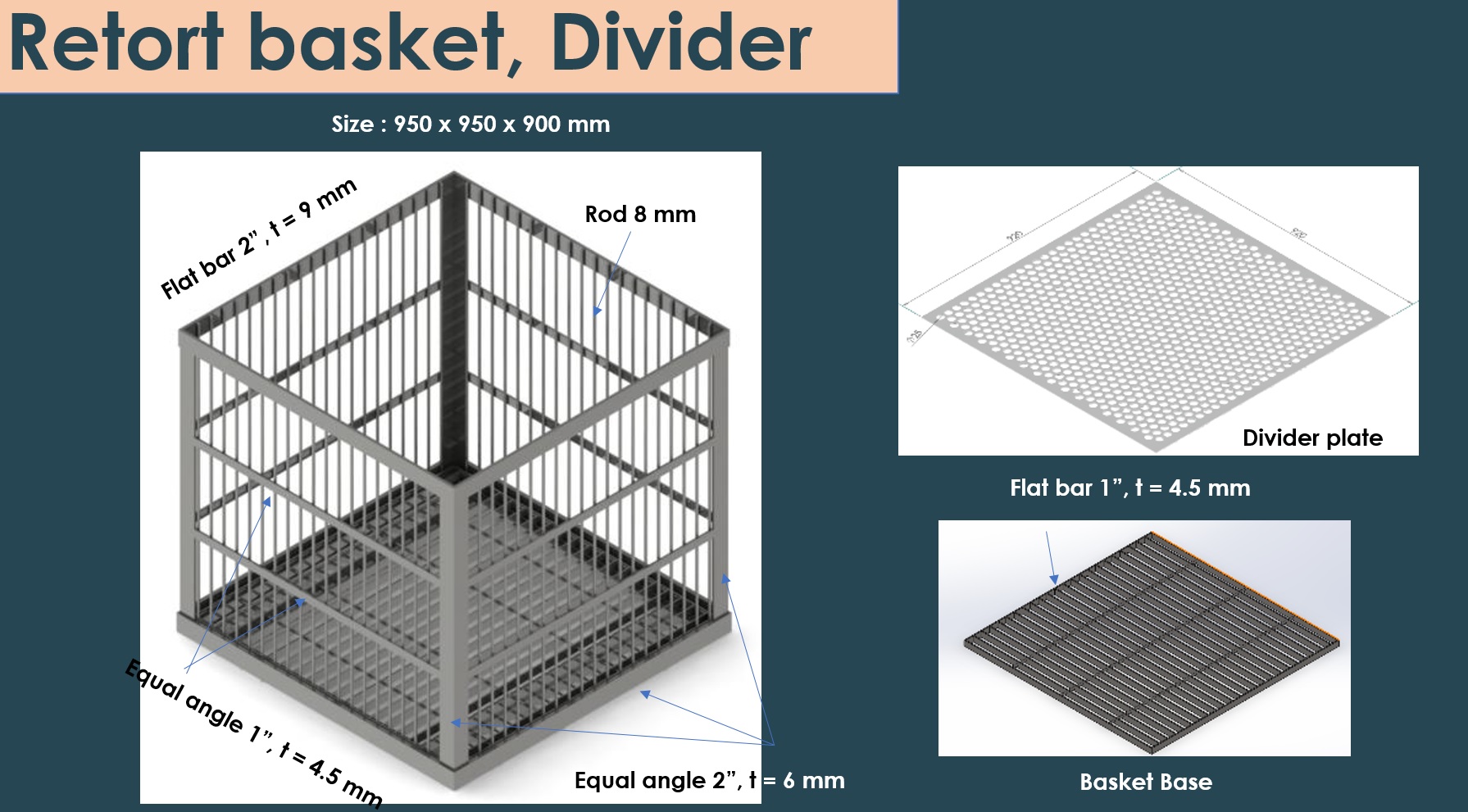

Retort System & Overhead Platform

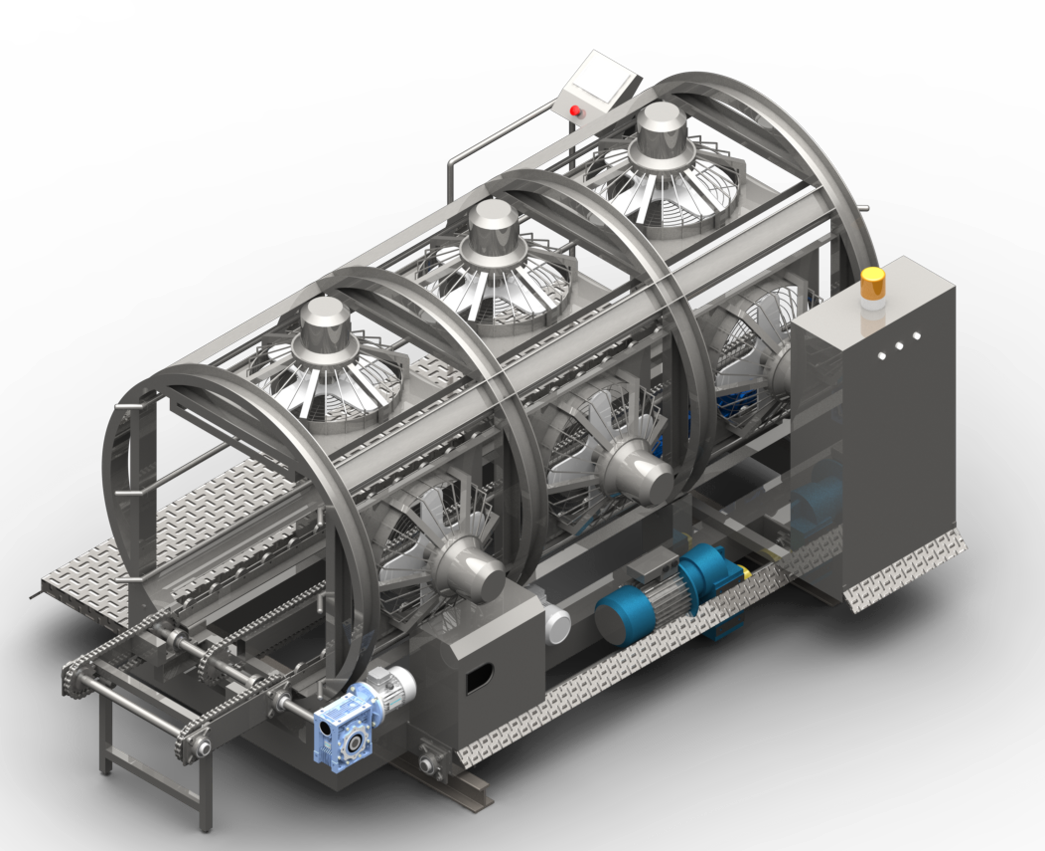

Dual mode retort

•Size : ID 1,400 mm, L 6,200 mm, t 6 mm

•Body : SUS304, t = 6 mm

•Door : 2 swing slip lock doors

•System : Water spray and direct steam

•Basket size : 950 x 950 x 900 mm

•Motor Gear : Sew 2 HP for feeding motor

•Chain : Stainless chain #80

•Roller : Stainless

•Pump : Calpeda with silicon o-ring viton 25 HP

•Plate heat exchanger : Funke (Germany)

•Flow meter : ABB Magnetic flow meter

•Control valve : Ari Armaturen (Steam, Air)

•Safety valve : Ari Armaturen 2” (set 2.5 bar)

•Insulation : Rockwool 2” with stainless cladding

•On-off valve : Sirca actuator with ball or butterfly

•PLC : Allen Bradley

•HMI : Weintek color touchscreen 10”

•Recorder : ABB temperature / pressure recorder

•Equipment : Schneider, Omron

•Control panel : SUS304

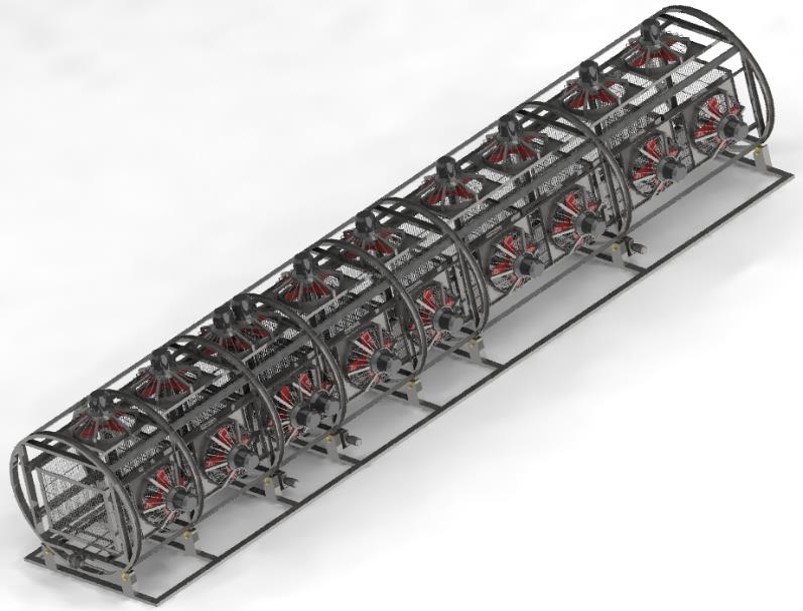

Outfeed Automatic Guided Vehicle (AGV) / Shutter

Outfeed 3 basket shuttles and tipper with rail system

•Size : ID 1,500 mm, L 3,000 mm

•Body : SUS304

•Motor Gear : Sew 2 HP for feeding motor• Chain : Stainless chain #80•Roller : Stainless

•Fan : Fan with motor 0.5 HP, 380V, 6 EA

•Swing arm to retort : SUS304, L 1,500 mm• Motor Gear : Sew 2 HP for rotating.

•PLC : Allen Bradley

•Equipment : Schneider, Omron•Control panel : SUS304 •Wheel : Stainless 4”

•Platform : SUS304, w=500 mm, 1 side

•Basket guide : Pipe ¾”•Motor Gear : Sew 0.5 HP for swing up and down(fix speed)

1 HP for feeding motor(fix speed)

2 HP for driving motor (fix speed)

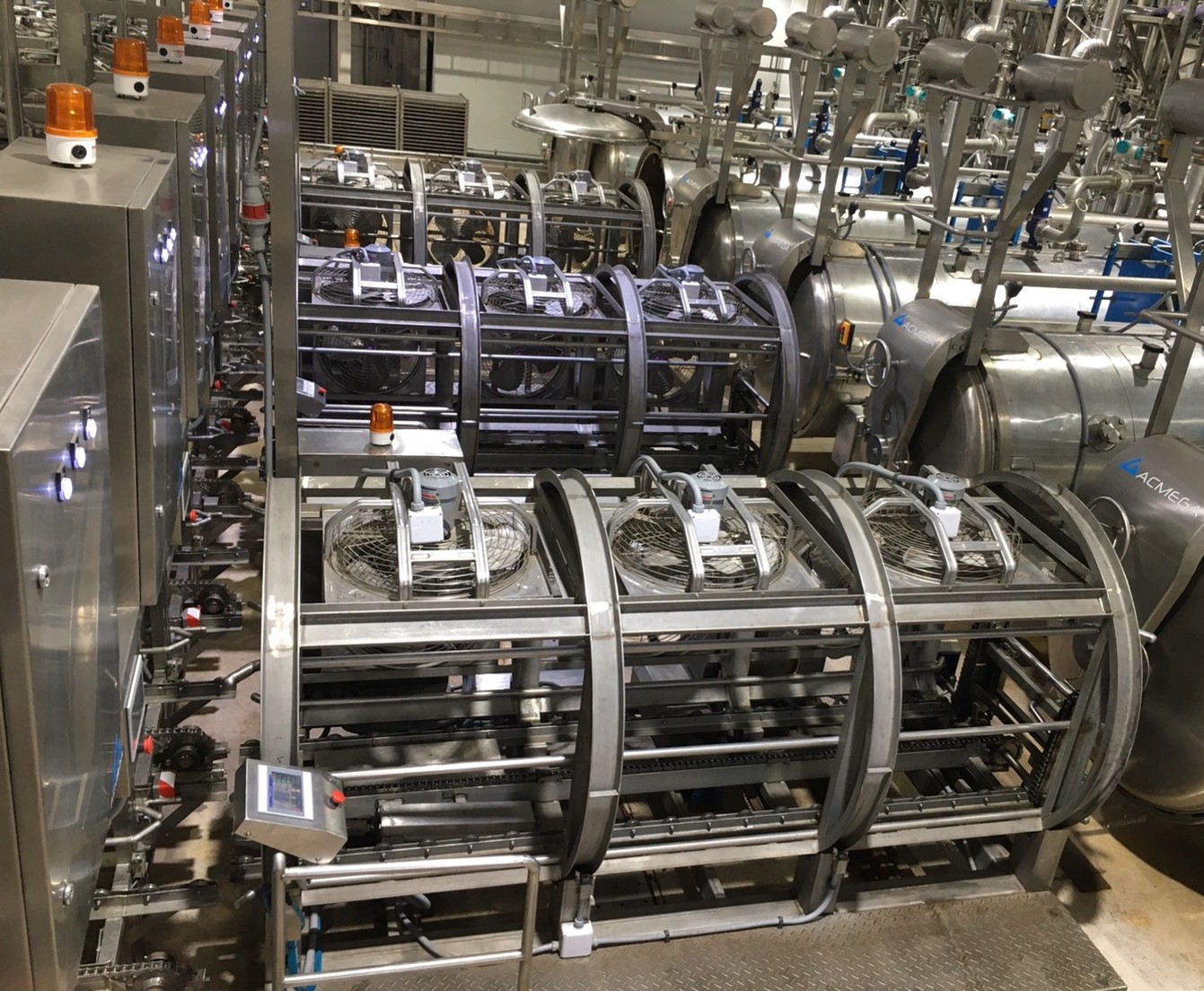

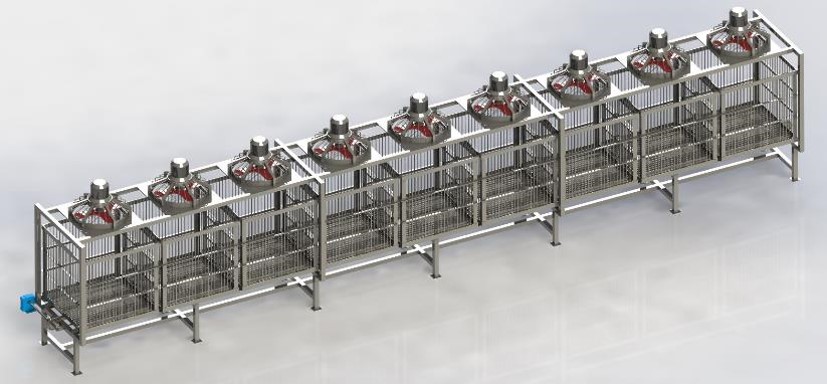

Basket Tripper & Buffer

Basket tipper

•Size : ID 1,500 mm, L 9,000 mm

•Body : SUS304 •Motor Gear : Sew 2 HP for feeding motor

•Chain : Stainless chain #80•Roller : Stainless

•Fan : Fan with motor 1 HP, 380V, 18 EA

•Swing arm to retort : SUS304, L 1,500 mm

•Motor Gear : Sew 2 HP for rotating.

•PLC : Allen Bradley

•Equipment : Schneider, Omron

•Control panel : SUS304

Basket buffer for 9 baskets

Size : ID 1,100 mm, L 9,000 mm

•Frame : SUS.304 Square pipe 2″ x 2″ x 1.5 mm

•Roller support : Angle 2″ x 2″ x 6 mm

•Motor Gear : Sew 2 HP for feeding motor

•Chain : “Kana” Stainless chain#80, 1 lanes

•Roller : Stainless 304, Dia. 70 mm x 15 mm, ball bearing

•Guide : Pipe SUS304, SCH#10 size 3/4″

•Fan : Fan with motor 0.5 HP, 380V, 9 EA

•PLC : Allen bradley micro800 series completed with weintek touchscreen 7″ (front)

•Remote HMI : Weintek touchscreen 7″ (1 set) (rear)

•Fan function : Individual fan, can start or stop 1 by 1• Equipment : Schneider, Omron

•Control panel : SUS304

Semi Automatic Can Unloading

Can unloading

•Size : 1,000 x 4,600 x 1,650 mm

•Frame : Pipe 3”x 1 1/2”,t 3 mm

•Frame : SUS.304 thickness 3 mm, C-Shape (Bending)

•Platform : SUS304, w=500 mm, 2 sides

•Motor Gear : Sew 2 HP, 30 rpm

•Capability : 180 – 300 cpm

•Belt : “Habasit / Rexnord” Plastic Modular belt, 4 lanes multi-speed for arrange can outfeed

•Pneumatic cylinder : SMC

•X lift: Hot Dip Galvanized Steel

•Hydraulic : SUS tank 40 l., motor 2 HP

•Inverter : Hitachi

•Sensor : Photo, Reed, Limit switch

•PLC : Allen bradley microligix1400 series completed with weintek touchscreen 7″

•Control panel : SUS304

•Mode: Semi automatic / Manual•

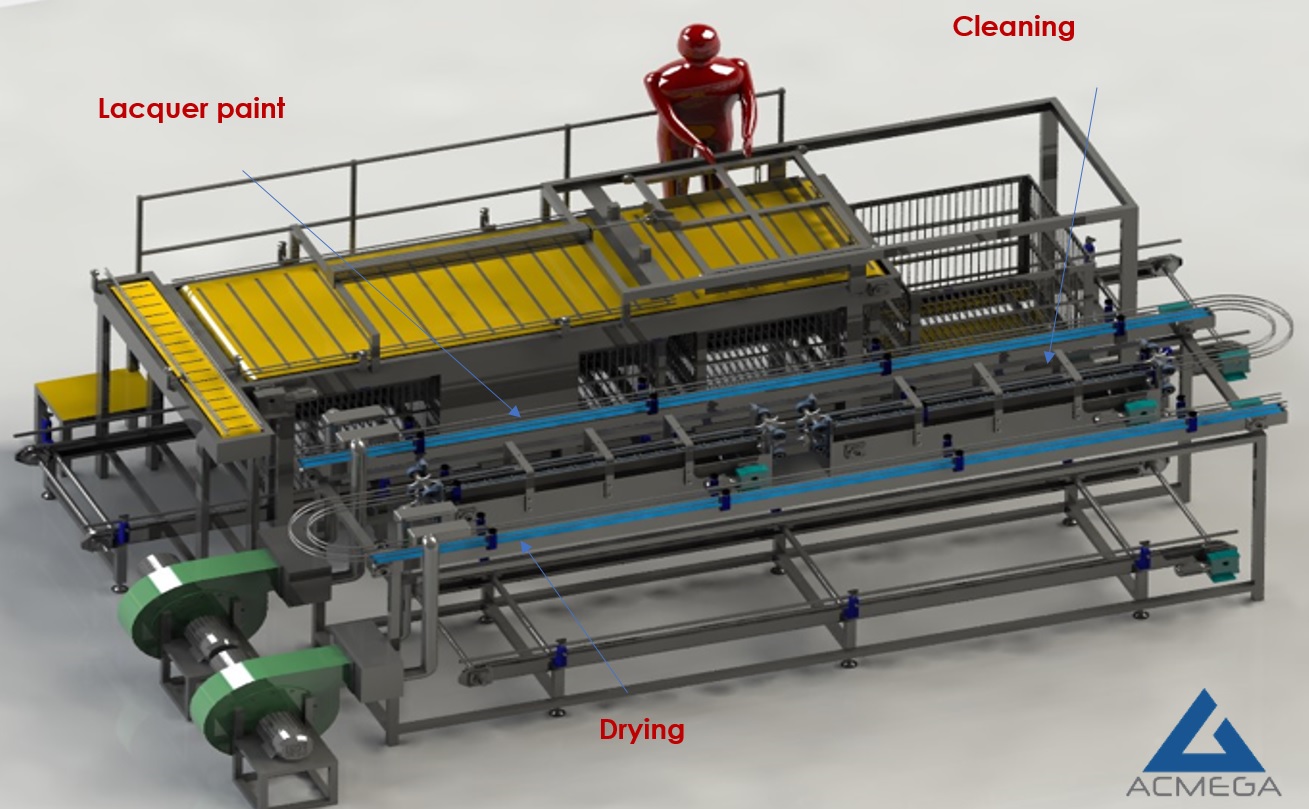

Cleaning-Lacquer-Drying

Air Blower De-Watering Conveyor

•Dimension :150 x 4,000 x 1,600 mm. (total)

•Frame : SUS.304 thickness 2 mm, C-Shape (Bending)

•Leg : Square pipe 40 x 40 x 1.5 mm

•Belt : Plastic belt, w=100 mm

•Motor drive : Motor gear 0.5 HP. 380 V. “SEW”

•Inverter : Hitachi

•PLC : Allen bradlley micro800 series

•Blower : Eurovent 20 HP

•Control panel : SUS304

Can Palletizer

Can palletizer

•Dimension : 2800 x 6,000 x 2,500 mm.

•Frame : Steel thickness 4.5 mm (Bending)

•Leg : Square pipe steel 6″ x 2“

•Belt : “Habasit / Rexnord” Plastic Modular belt , w 1000 mm.

•Motor drive : Motor gear 1 HP. 380 V. “SEW“

•Pneumatic cylinblder :

•Pneumatic solenoid valve : SMC

•Magnet head : Up-down by pneumatic cylinder, moving by motor “SEW“

•Chain lift : chain#80, 4 sets, up-down by motor gear “SEW“

•Pallet feed out motor : Motor gear 2 HP. 380 V. , “SEW”

•PLC : Allen Bradley

•Control panel :SUS304•Option : Pneumatic pusher

Semi Automation Unloader Tray Stacker, Cup & Pouch

Semi-Automatic Unload tray stacker – Cup & Pouch

For pouch :Dimension :1,250 x 3,500 x 2,950 mm.

For cup :Dimension :1,250 x 3,500 x 2,950 mm.

Specification

•Main Frame : SUS.304 Square pipe 2″ x 2″ x 1.5 mm

•Support Frame : SUS.304 Square pipe 1 1/2″ x 1 1/2″ x 1.5 mm

•Buffer table : SUS304 sheet, size 1000 x 1000 x 1.5 mm

•X- Lift : Mild steel with hot dip galvanized with Hydraulic power unit set

•PLC : Allen bradley completed with weintek touchscreen 7“

•Servo motor : Mitsubishi for vertical movement

•Inverter : Hitachi

•PU belt with motor sew 0.5 HP

Cup & Pouch Conveyor Dryer

Pouch drying conveyor

Specification

•Dimension :1,200 x 4,500 x 2,250 mm. (conveyor 1,800 mm)

•Main Frame : SUS.304 Square pipe 2″ x 2″ x 1.5 mm

•Drying box : SUS.304 sheet, 2 side door, L 1,200 mm

•Belt : Stainless wire mesh, w 400 mm., L 2,500 mm

•Motor drive : Motor gear 0.5 HP. 380 V. “SEW”

•Inverter : Hitachi• Blower : High speed blower “Sonic”, 20HP

•Wire Rope Sling conveyor height adjustable : Yes up to pouch thickness• Inverter : HitachiPU belt with motor Sew 0.5 HP

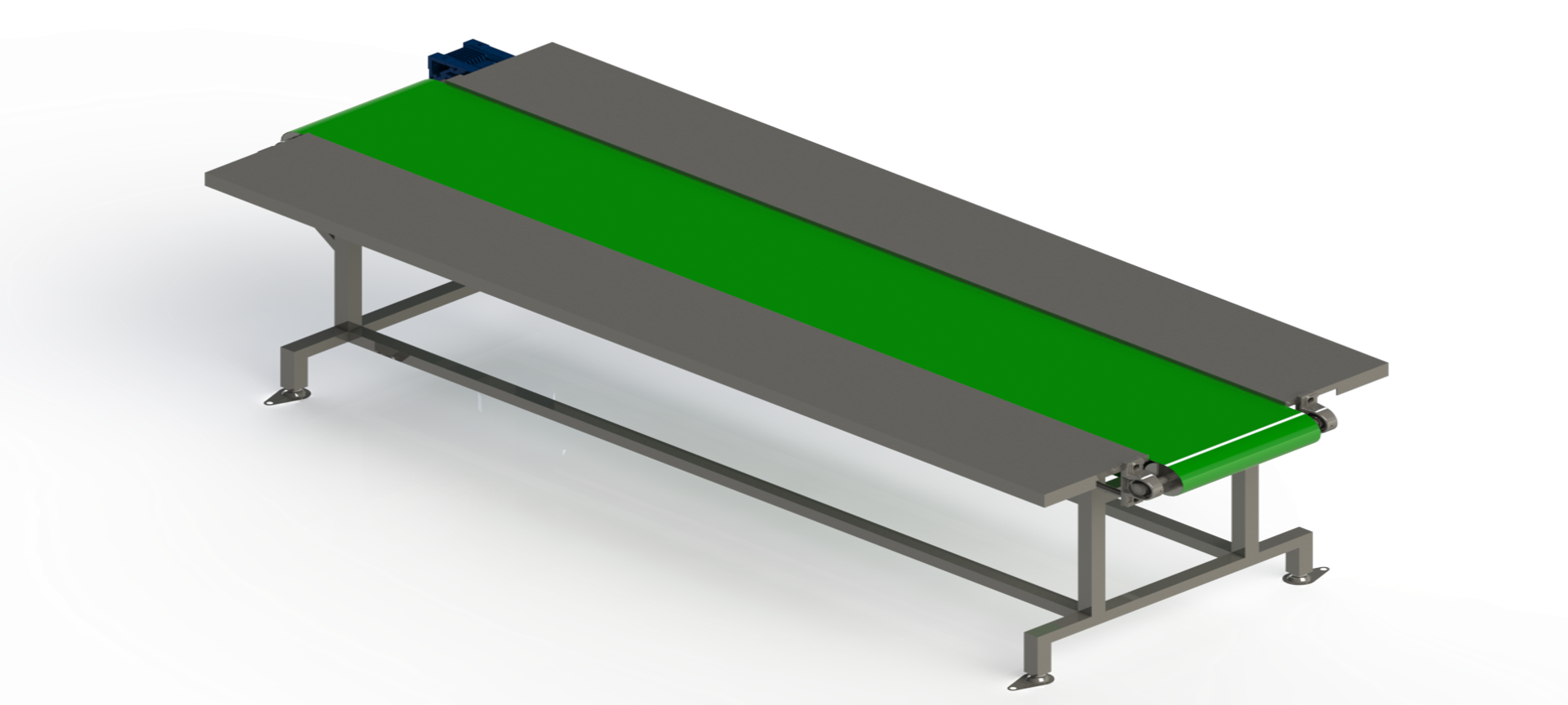

Packing Conveyor

Packing conveyor

•Dimension :500 x 2,000 x 800 mm.Main

•Main Frame : SUS.304 Square pipe 1 1/2″ x 1 1/2″ x 1.5 mm

•Belt : PVC belt, green, w 400 mm., t 2 mm, L 2000 mm

•Table : SUS304 size W260 x L1700 x 1.5 mm, 2 sides

•Motor drive : Motor gear 0.5 HP. 380 V. “SEW”