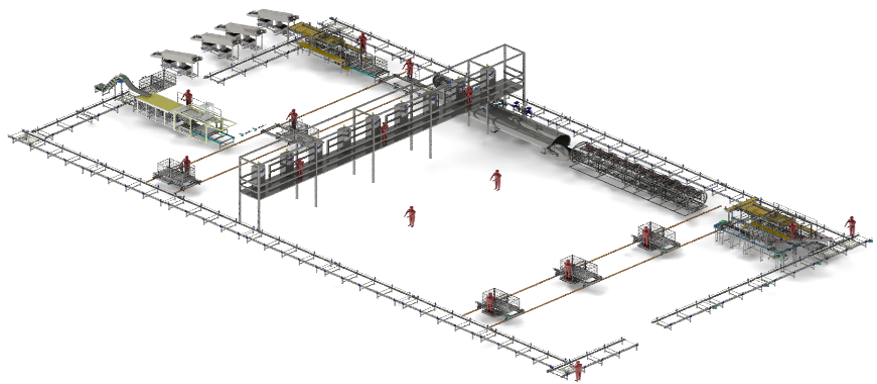

CONVEYOR AUTOMATION SYSTEM

Can-Cup & Pouch Conveyor Automation System

Conceptual Design

- Conveyor automation system-1

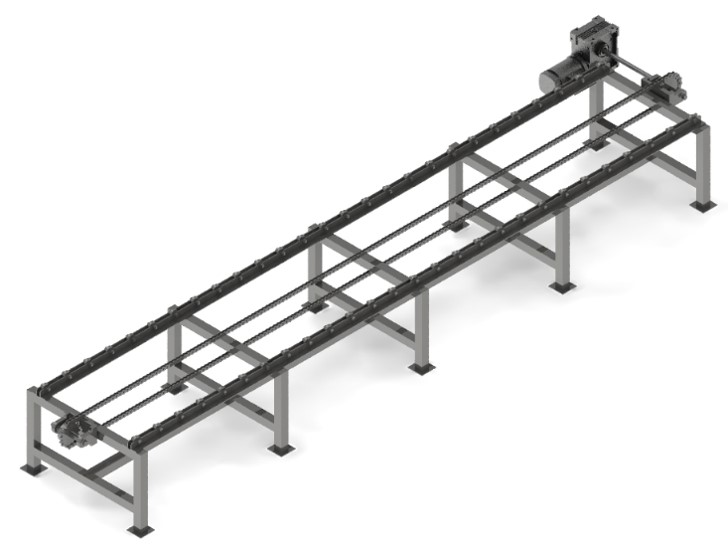

Specification

•Dimension :1,000 x 6,000 x 500 mm. (6 m x 7 EA)

•Dimension :1,000 x 7,500 x 500 mm. (7.5 m x 3 EA)

•Frame : SUS304, C shape, t = 3 mm

•Leg : Square pipe 2”, t = 1.5 mm

•Basket guide : Pipe ¾”

•Motor Gear : Sew 2 HP (fix speed) •Chain : “Kana” Stainless chain#60, 2 lanes

•PLC : Allen Bradley

•HMI : Weintek 7” (1 main, 1 slave) •Control panel : SUS304

•Turning unit : Pneumatic Piston with Lifter (11 EA)

•Frame : SUS.304 Square pipe 1 1/2″ x 1 1/2″, 1.5 mm

•Motor drive : Motor gear 0.5 HP. 380 V. “SEW”